Pipe clamps are used quite often in woodwork and piping and their capacity depends on the length of the pipe. A clamp is primarily used to connect piping and woodwork, which is why this can be used as an alternative to having the pipes welded. If you are wondering can pipe clamps be used for exhaust pipes, then you are in for a treat as we provide you with additional knowledge on this matter.

Yes! You can definitely use pipe clamps to put an exhaust pipe together. Professional welders prefer to use a pipe clamp than welding because while the latter makes the pipe stronger, the former makes it stronger, equally. This is why using the right clamp for the exhaust pipes can get the work done quite easier than having to use welding machines.

If you are curious and want to know more about using pipe clamps on exhaust pipes and you want to know its benefits, then continue reading as we provide you with in-depth research regarding this matter.

Clamping exhaust pipes together is possible

Yes, you read it right! It is possible to clamp exhaust pipes together; even professional welders prefer to have the pipes clamped versus welding. Exhaust clamps play an important role in automotive vehicles because it helps in reducing noise and making sure that there is no leak with the emission. The same goes for exhaust pipes to be used in any other machine.

Further information about exhaust pipes provides that the latter is meant to provide or direct the fumes out of the engines or any machines, and it helps in keeping away carbon monoxide from the vehicle. One must also take note of the fact that when you opt to clamp your exhaust pipes, you no longer have to weld the clamp itself.

Clamping an exhaust pipe will provide almost the same stability as your exhaust pipe system and are easier to repair. You just need some good equipment which will be discussed further below. Another advantage of using a clamp is the fact that it is easier to maneuver and most likely can be done by yourself.

Check out this exhaust clamp at Amazon.

How Do You Clamp Exhaust Pipes?

Of course, you have to know the do's and don'ts if you are considering using an exhaust clamp. Below are lists of items and things that you should do to use the clamp properly.

- First and foremost, you should prepare your safety equipment such as safety goggles, work gloves, and boots to avoid any casualty.

- Second, loosen the U-bolt of the clamp on which you want to.

- Third, remove the Hex nut from the U-Bolt.

- Fourth, attach the saddle on the exhaust pipe but make sure to not tighten the Hex nut just yet.

- Fifth, exert pressure on the pipe to make sure that it is nicely gripped.

- Sixth, fix the selected socket to the hex nut, and only then will you be allowed to tighten the Hex nut.

- Check if the nuts in the clamp are tight.

- Lastly, put all the clamped exhaust pipes together and make sure that all of them are tight.

Check out these Dewalt anti-fog safety goggles at Amazon.

How To Seal Exhaust Clamps Without Welding

You are probably wondering if it would be possible to weld an exhaust clamp and, if not, what are the ways to make the clamp last longer. You can opt to do welding on the clamp if you want it to be more secured, but that would be exerting unnecessary effort and time, not to mention the amount of labor you will be doing.

To seal your clamp, you can do the following:

Use an exhaust clamp

Your exhaust pipe can be as good as welded by using an exhaust clamp and screwing it properly.

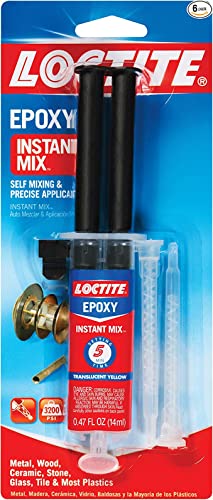

Sealing the exhaust using epoxy

Sealing an exhaust pipe can help ensure there will not be any leak once the exhaust starts to operate.

Seal it by using an exhaust tape

Wrap the tape around the whole to avoid leaks.

Seal it by using an aluminum patch

Make sure that it can be used along with the epoxy to ensure there will be no leaking in the future.

Check out this Loctite epoxy at Amazon.

What is the difference between clamping your exhaust pipes and welding?

Earlier in this blog, you were already informed of the preference of using clamp over welding, but to further widen your knowledge on this matter, we have provided you below with well-researched information that can hopefully be of help to you.

Clamp:

- As for how it should be used: this is used to join two pipes.

- As for accuracy: the temporary joints created last longer than welding.

- As for durability: this can be less durable but more stable.

- As for skill: you can do this on your own, which means you don't need to spend money on professional welders.

- As for the cost: this is more cost-effective.

- As for the usage of safety equipment: there is no need to use much safety equipment. Goggles and a working glove will be enough.

- As for power supply: luckily, with an exhaust clamp, you don't have to spend money on a power supply.

- As for installation: you only have to connect the exhaust pipes.

Welding:

- As for how it should be used: this is usually used for permanent joints.

- As for accuracy: the joints are not temporary, which makes them stronger and more accurate.

- As for durability: this is long-lasting.

- As for skill: since welding deals with fire and meticulous inspections, hiring a professional welder should be had.

- As for the cost: this is considerably more costly than a clamp because aside from paying a professional welder, you also need to spend on materials and power.

- As for the usage of safety equipment: the professional welder must be equipped with proper safety wear because he/she will be dealing with power and fire.

- As for power supply: using a welding machine includes a power supply to function, which is why it can also get costly.

Check out this Yeswelder welding helmet at Amazon.

To further elaborate on the matter, the vital information that is needed when differentiating the two is how they work. Exhaust clamps are used to connect two pipes strongly or for repairing any damaged pipes. As for welding, this is used for connecting exhaust pipes which are proven to be long-lasting and highly durable.

Furthermore, it is worth noting that clamping an exhaust pipe can make it lasts for as long as ten years depending on how it is maintained and used it's just that welding exhaust pipes make them stronger than simply using a clamp.

Check out this insightful post on How long should an exhaust pipe lasts.

Different types of clamps suitable for exhaust pipes

To do a proper job with clamping your exhaust pipe, you should first know the different kinds of clamps that are suitable for whichever pipe you use. Below are lists of types of clamps suitable for your exhaust pipe.

- Band Clamp: a band clamp is a multi-used clamp and is usually easy to fit with almost every exhaust pipe. This is either made up of aluminum, galvanized, or stainless steel.

- U-Bolt clamp: this is usually used to support pipe works that serve as a passage for fluids and gases.

- V-Bolt Clamp: this clamp is usually used in heavy-duty and high-functioning vehicles due to its tight sealing capabilities.

- T-Bolt clamp/Hose clamp: this is the most versatile clamp as it can be used on any pipe applications such as water and gasoline. This is also made of solid brass metal, making it durable.

- Ball and socket: although not quite considered a clamp, it still serves its purpose in connecting pipes together. Its feature includes having a rounded ball end that fits inside a flared socket and where the two halves are compressed together.

You can also check out this post titled: Exhaust Pipe Clogged With Ice – What To Do?

Conclusion

To conclude, you can clamp your exhaust pipe instead of welding it. However, you should also consider factors such as cost, durability, longevity, and the proper clamp to use on your pipe. If you opt to go with welding, make sure to contact a professional welder to avoid accidents and to make sure that the pipe is properly connected.